David J. Nims | Phone: 425-397-9814 | Fax: 425-397-0489 | nimsd@aol.com |

These were troubled times for Optrotech in their primary business, optical inspections systems for the printed circuit board manufacturing industry. A new Israeli competitor, Orbot, had appeared on the scene with a product that leap-frogged Optrotech's then current products. This forced Optrotech to launch its new product, the Vision 206 way before it was ready.

When I joined the company, the first Vision 206's were being delivered ... very green, very unreliable, and missing all of the promised options, which severely limited their applications. My major challenge was to keep this situation stable while the R&D people solved the problems and completed development. This we managed to do, via a real team effort and intense customer interaction and support. I reorganized the western office, hiring a Director of Operations, and gave him authority over the daily priorities of the customer support people in the west. His full time assignment was to stick-handle the support issues with our big west-coast customers. I handled the east and midwest personally. It took two years to really resolve this situation.

In the meantime, I had to keep sales up. My background was strongest on the Imaging side of Optrotech's business. On this side, the strength of Optrotech's Image 2000 system was in its production front-end, sort of a manufacturing CAD system, that would accept the PCB design files, and lay them out multiple-up on a panel to be built, adding all the ancillary information such as drill-test patterns, quality-control features, product numbers, etc. The weakness was their actual imaging engine, which they purchased on an OEM basis from Hell in Germany. It's size and resolution was not competitive with MDA's FIRE 9000, and Optrotech was losing most of the business in the lucrative imaging service bureau market. While attending my first quarterly meeting in Tel Aviv, I recommended that Optrotech initiate a joint-development with CREO in Canada, to build a new, state-of-the-art photoplotter. I had worked with the people from CREO, and trusted they could do this quickly, and cost-effectively ... at low risk. Partly because Optrotch had its hands full with other problems, they decided to go ahead with this plan ... and the Image 5000 born.

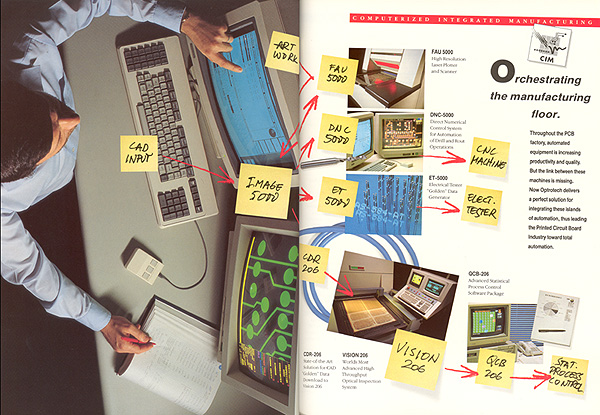

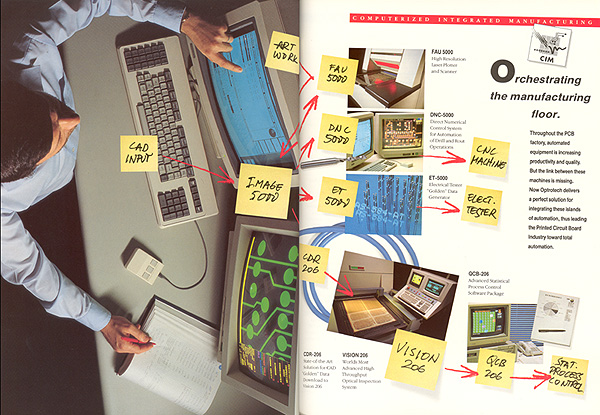

My other major contribution to Optrotech's product strategy was to reposition its two main products as part of a CIM (computer-integrated manufacturing) system. At the time, Optrotech was organized vertically around its two major product lines, the Image systems, which produced film used to expose the circuit pattern on the printed circuit boards, and the Vision systems, which were used to optically inspect the various layers of the printed circuit boards as they were being manufactured. This organization was reflected in the subsidiaries. Even in the trades shows, the two product lines had separate areas in the booths, and were promoted separately.

My idea was to position the Image system as the source for all the computer-aided tooling needed by the PCB manufacturers. Since it laid out the panels, it was really best suited for this purpose. With minimal development cost, it could provide control information to the drills and routers, test pad postion info to the electrical testers, raster image data to the photoploters, and design reference information to the optical inspection systems.

Optrotech signed on to this strategy, as shown in this excerpt from their 1988 annual report below.

|

The impact that the CIM strategy had on Optrotech's business was more remarkable than I had anticipated. For Nepcon in 1988, our major trade show, I had a new booth built, where all our products were laid out as they would be on a shop floor, and our integrated product-line strategy was described in a single presentation. Our customers were very receptive to this strategy, and it gave us an effective competitive tool to resume agressive marketing of the Vision 206. In response, Orbot tried to put together its own CIM strategy via partnerships with other companies which marketed photplotters, but the industry knew this was just a marketing ploy and there was no substance or commitment behind it.

After 3 years, life in Optrotech's sales subsidaries was approaching more of a routine. The Vision 206 had finally matured, and we had a good long-term vision and strategy for the PCB market. The company was finally able to consider expansion into other markets. I had an interest in helping with this, and after discussions with Shlomo Barak, President and CEO of Optrotech, I was offered the position of V.P. Business Development, reporting directly to Shlomo. During my 3-years running the U.S. operation, our sales nearly doubled, and our market share in the Image side of the business had also doubled.

In my business development role, I spent my time on two major projects. The first was to explore the possibility of developing a processless film for use in our photoplotters. After an in-depth study of the market need and the cost-benefits of using such a film, I initiated discussions with Polaroid, Dupont, and Kodak, which all claimed to have applicable technology. Eventually these efforts resulted in the signing of a joint development agreement with Kodak to pursue this.

My second project was in the graphic arts market. After the Image 5000 had been developed and successfully launched, Optrotech began an off-site development project to take this product into the graphic arts market. However, business was slow in the PCB industry, and and Orbot continued its agressive sales tactics in the field. Operating margins were tight. Optrotech started having cash flow problems, and was on the verge of shutting down this fledgling graphic arts team.

Before taking this step, Shlomo asked me to take a look at the market for this new product, targeted at producing full, 8-page signatures, to be used for direct exposure of printing plates. I spent a couple of weeks talking to potential users of this product, and determined that there would be a strong demand, particularly by book printers and printers of software documentation.

Based on this input, the development was continued, and the SPrint 110 was launched. Shlomo had asked me to lead this introduction, so, as V.P. of the new Graphic Arts Division, I took the SPrint 110 to Print '91 in Chicago, the biggest graphic arts trade show of the year. We sold 10 systems off the floor in Chicago, and a new business for Optrotech was launched.

We soon hired my replacement, to continue the thrust into the graphic arts market, and I resumed my business development role. However, in Israel, responding to government and business pressures, Optrotech and Orbot announced an agreement to merge the two companies, and to form a new company, Orbotech. Orbot's people ended up with control, and the word was out that all senior Optrotech people would be terminated.

While launching the graphic arts product, I got to know Scenicsoft, a software company based in Seattle. The SPrint 110 was packaged with imposition software, which laid out the various pages on a press sheet, and added ancillary features, performing much the same function as the Image 2000 front-end did in the PCB application. In this case we were using Impostrip, an off-the-shelf product from Ultimate Technologies in Canada. We felt the price they were charging was much too high, and their support was inadequate. I started looking for an alternative, and found Scenicsoft. They had software technology that could serve as a foundation for imposition software, were quite technically knowledgeable, and easy to work with. On my recommendation, Optrotech initiated a development contract with Scenicsoft under which they would develop and market imposition software. Our savings on the first 10 copies would more than pay back the develpment costs.

When news of the Optrotech/Orbot merger hit and the implications became clear, I started considering my next career move. I wanted to get back to the west, where our families lived. I initiated a conversation with Scenicsoft, and we came to an agreement under which I would join them as V.P. Sales and Marketing.